NIR light is becoming pervasive within products to improve perception, functionality, and safety. NIR is used in applications ranging from LiDAR & automotive ADAS to machine vision systems, night vision cameras, IR remotes, touch screens, and various medical and therapeutic uses.

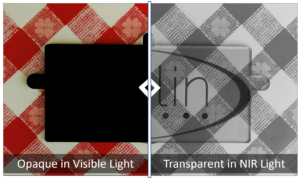

NIR illumination and detection electronics often incorporate a protective cover or lens that appears black or visibly opaque. The black cover on the end of a TV remote or a dome around a night vision security camera are examples of visible opaque, NIR transmitting materials. They obscure electronics and reduce heat from Solar’s visual spectrum while efficiently transmitting NIR portion of light. They also expand design options and minimize the appearance of welds created by NIR lasers in part joining operations.

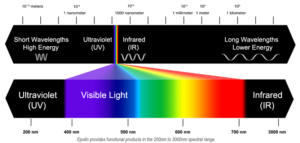

NIR light, traditionally classified as starting at 780nm, has several advantages over visual light including no glare, lower diffraction under problematic atmospheric conditions, and increased transmission through many materials compared to visible light. Another advantage is that NIR wavelengths were largely presumed to be invisible to human sight as human eye sensitivity dramatically decreases at wavelengths longer than 700nm.

More recent studies indicate that some human eyes can detect a visible light response from the NIR light above 780nm. One study demonstrated that the human eye may respond to radiation up as far as 1064nm depending on the light intensity, duration, angle, location of the image on the retina, as well as other factors.1 As NIR light applications expanded international standards were established to limit infrared exposure to the eye. IEC-62471 covers LEDs, while lasers are covered by IEC-60825.2

Sensors, like human eyes, are also susceptible to environmental factors that can reduce performance. Fortunately, Visible Opaque materials can be utilized to pass desired signals while rejecting noise or interference.

LiDAR-Functional Visible Opaque Applications:

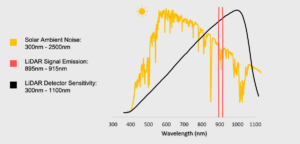

LiDAR is a highly capable environmental mapping technology enabling achievement of higher levels of vehicle autonomy. LiDAR units produce a narrow band of 905nm +/-10nm of NIR light which reflects off illuminated objects and returns to the detector in the unit. If the detector receives a clean return signal it produces a highly accurate positional map of the environment based on those reflections.

A typical silicon-based LiDAR detector chip has high sensitivity around the narrow LiDAR signal range, but also has sensitivity to shorter NIR and visible wavelengths. Ambient sunlight reaching the earth’s surface contains a wide range of UV, visible, and NIR light which combined with interference from other NIR sources like LEDs or other lasers can saturate the LiDAR detector thereby reducing overall system performance.

Application of Visible Opaque materials formulated with specific NIR absorbers effectively filters both visual and NIR noise that lies outside of the targeted LiDAR signal band. Such light management techniques can dramatically improve LiDAR resolution and range.

Interior ADAS Visible Opaque Applications:

Beyond exterior applications, in-vehicle ADAS applications including driver alertness & occupant sensing applications increasingly rely upon NIR light management. Such applications utilize NIR LEDs to illuminate objects via directed or flood lighting of the cabin. Some occupants may perceive such emissions once their eyes have adjusted to low visible light conditions while driving at night.

Visible opaque formulations tailored around specific illumination spectra can mitigate potential occupant distraction. As facial and gesture recognition systems evolve, Epolin can customize light management solutions whether they are based on LED or laser technology.

Product Options:

These visible opaque, NIR transmitting functional materials may be sourced as an Epolight® dye blend in powder form for compounding3 or as ready to mold Luminate™ compounded thermoplastic pellet. Ink or thin film supply forms are also available.

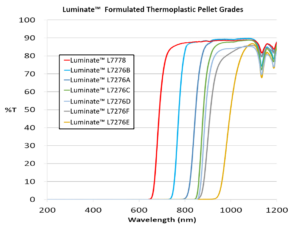

L7778: An economic solution to obscure device electronics like IR remotes.

L7276B: Produces a deep, aesthetically appealing black that can formulated into various shades of grey. Suitable for NIR laser welding and joining operations.

L7276A: Used to reduce solar and NIR interference to improve 905nm LiDAR signal fidelity. Reduces red glow from 850nm illumination in security camera applications. High transmission above 880nm.

L7276F: Mitigates the red glow from 940nm LEDs for applications requiring covert illumination concealment.

L7276E: Begins to transmit above 950nm with good transmission over 1050nm.

Our knowledgeable technical team can provide timely, optimized, product recommendations for your specific application. Should a novel approach be required, our R&D group can develop new materials targeted to your unique specifications. Epolin’s “Concierge Chemistry” approach to product development and light management expertise allow us to address a wide range of challenging opportunities.

About Epolin

For over 30 years Epolin has been the leader in providing near infrared, visible, and UV absorbing dyes that can be used individually or combined into complex dye formulations to manage light for applications ranging from laser & welding protection to performance eyewear, digital displays & filters, and night vision products. Epolin continues to innovate, creating new formulations to serve expanding applications within the autonomous vehicle, augmented reality, and medical testing markets as well as through new formats like film & sheet extrusion, liquid casting, lamination, pressure sensitive adhesives, and solvent-borne coating applications

Our high-quality materials add performance and value in optimizing IR light absorbance and visible light transmittance in a myriad of Injection Moldable thermoplastic and thermoset polymeric materials such as polycarbonate, acrylic, cellulose propionate, polystyrene, PVC, COC and polyurethane.

We would be pleased to work with you to create a product that meets your specific spectral requirements: epolin.com

Click Here To Download A PDF Version Of This Article

References & Notes:

3 Compounding of thermally sensitive NIR dyes requires specialized knowledge and a clean compounding environment.