Newark, NJ – Epolin, a leader in high-performance light absorbing dyes and materials for optical applications, proudly announces the launch of its latest welding eye protection formulations. These products are designed to meet the rigorous requirements of the new ISO 16321 standard.

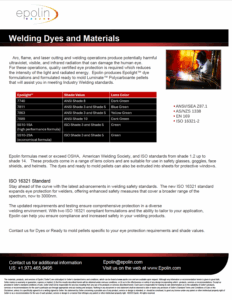

Arc, flame, and laser welding operations generate hazardous ultraviolet, visible, and infrared radiation that can severely damage the human eye. To address these risks, Epolin has developed Epolight™ dye formulations and Luminate™ ready-to-mold thermoplastic pellets, supporting enhanced safety for a wide range of welding environments.

The new ISO 16321 standard expands eye protection coverage to 3000 nm, ensuring broader spectrum protection for welders. Epolin now offers two ISO 16321-compliant formulations with the flexibility to tailor solutions to specific application and shade requirements, ensuring both compliance and superior performance.

Suitable for a wide range of applications, these materials are ideal for safety glasses, goggles, face shields, helmets, and extruded protective sheets. Epolin’s welding protection solutions also meet or exceed OSHA and American Welding Society (AWS) standards, covering shade levels from 1.2 to 14.

“At Epolin, we are committed to staying ahead of evolving safety standards and providing our customers with the most advanced, reliable eye protection solutions,” said Don Tibbitt. “Our new ISO 16321-compliant products demonstrate that commitment, delivering enhanced safety without compromising optical performance.”

For more information you can download the new product flyer here:Epolin Welding ISO 16321 Standards

Or request materials tailored to your specific eye protection requirements, contact:

📧 Epolin@epolin.com.

📞 +1.973.465.9495

🌐 www.epolin.com